Modeling of Active Gap Capacitance Electrical Discharge Machining

Wang X, Guo H, Tu J, et al. Modeling of Active Gap Capacitance Electrical Discharge Machining[J]. Journal of Manufacturing Science and Engineering, 2021, 143(6): 061012.

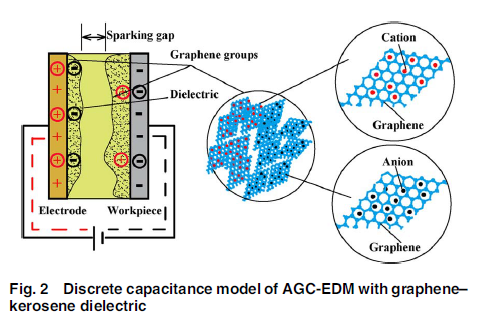

Active gap capacitance electrical discharge machining (AGC-EDM) is a high-speed EDM method for machining polycrystalline diamond tools utilizing the active capacitive effect and powder mixing effect formed by the kerosene dielectric added with graphene particles. The capacitive effect increases the discharge energy and explosive force, which in turn influences the material removal efficiency; the powder-mixed effect changes the states of dielectric and forms a non-fixed gap discharge process. Take into account these two aspects, a new discharge mechanism of AGC-EDM is proposed to describe the discharge process. Capacitance characteristics and chain stacking process of graphene-kerosene dielectrics are verified by experimental results. The material removal rate, relative electrode wear, and surface roughness are discussed with the pulse duration, peak current, and graphene concentration to study the theories of the new EDM process.