Optimisation of Process Parameters for Electrochemical Machining of a Curved Hole

Zhou X, Jiang Y, Gan W, et al. Optimisation of Process Parameters for Electrochemical Machining of a Curved Hole[J]. INTERNATIONAL JOURNAL OF ELECTROCHEMICAL SCIENCE, 2021, 16(8).

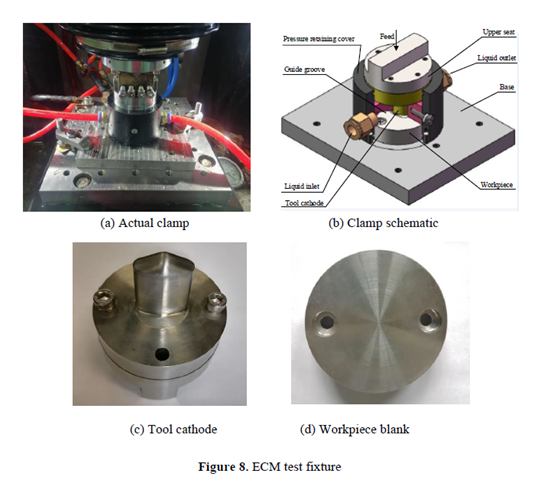

A curved hole surface can be formed by a rotating contour tool. Owing to the shape and the material hardness, traditional cutting methods suffer from significant tool wear and poor machining efficiency. In this research we used the electrochemical machining method (ECM), in which there is no wear of tool cathode, no stress on the workpiece, high processing efficiency, and high quality machining of the curved hole is achieved. The machining gap is the key factor determining the effectiveness of ECM and the machining accuracy. In this study, numerical simulations of the ECM process were carried out. Five factors and five levels of orthogonal experiments were carried out on the main parameters affecting the machining balance gap. The optimal technological parameters consisting of the applied voltage, feed speed, initial gap, pulse duty cycle, and pulse frequency were obtained using the range analysis method. The optimized parameters were verified experimentally, and the surface roughness of the sample reached 0.613 μm, which meets the requirements of engineering applications.