Alternating Energy Electrical Discharge Machining of Titanium Alloy Using a WC-PCD Electrode

Wang X, Li C, Guo H, et al. Alternating Energy Electrical Discharge Machining of Titanium Alloy Using a WC-PCD Electrode[J]. Journal of Manufacturing Processes, 2020, 60: 37-47.

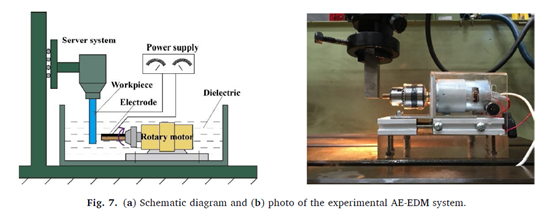

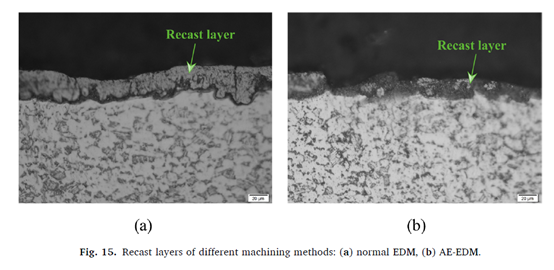

This paper presents a novel electrical discharge machining method, alternating energy electrical discharge machining (AE-EDM), for the machining and surface modification of the workpiece. A tungsten carbide–polycrystalline diamond (WC-PCD) combined electrode was used in the EDM process to change discharge energy alternately, resulting in lower surface roughness and higher surface hardness. Based on the relationship between discharge current and plasma channel extension, principles and discharge models of AE-EDM were established. To validate the theory and assumptions and investigate the effectiveness of the new approach, the discharge performance of PCD was analyzed and a comparative study was conducted. Experimental results show that the sustaining voltage of the plasma in the machining of the PCD material is 19 V, and a fraction of the energy was consumed by the bulk resistance of the PCD, which reduces the energy for eroding material. The surface roughness of the workpiece machined with AE-EDM was found to be reduced by 40% compared to normal EDM using copper electrodes, while the average surface hardness was improved by 28.6% and the thickness of the recast layer was decreased.